Combination of Technical Expertise and Innovative Solutions.

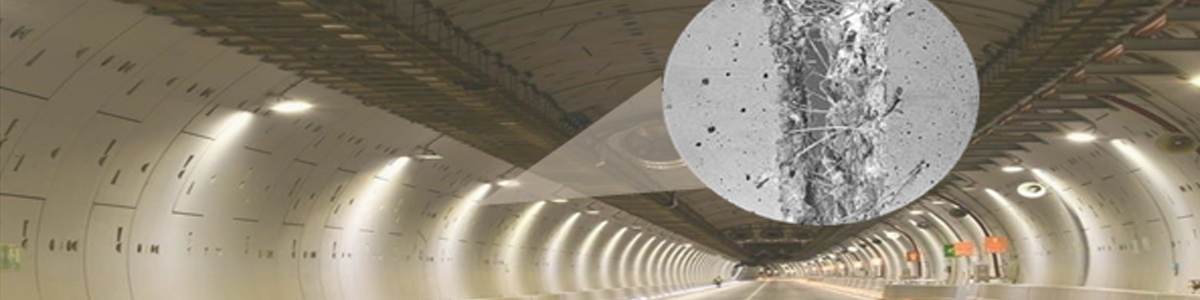

Macro synthetic fiber ENEⓔ Polymacro PM48 has been specifically designed for shotcrete applications and tunnel linings to increase impact resistance.

Homogeneous fiber distribution makes it possible to absorb energy in any point and any direction of the concrete segment; cracking resistance is considerably improved. To increase reliability and service life of concrete linings, fibers have been designed to increase crack control under high pressure and minimize spalling in conjunction points.

Synthetic fiber prevents the risk of corrosion compared to steel fiber and wire mesh reinforcement. Due to 0.91 g/cm³ gravity, high number of fibers can be obtained in lower weights.

Thus, higher and three-dimensional reinforcement of concrete mix is achieved.

Usage Instructions

Depending on the project requirements, recommended dosages vary between 1 kg/m³ and 3 kg/m³ Homogeneous mixture is obtained by addition of ENEⓔ Polymacro PM48 to the aggrege band at the concrete batching plant or by mixing in a high speed concrete mixer for at least 5 minutes in the field. It is recommended to use plasticizer additives in high doses.

Applications

Field & Floor Applications

• Industrial Floors

• Underground and Walk Ways

• Concrete Roads

• Logistics Facility Floors

Coastal Structures & Ports

• Ports and Quays

• Shipyard

• Marinas

Water Control Structures

• Hydroelectric Power Plant

• Irrigation Projects

• Channels

• Drinking Water Projects

Residential Applications

• Parking Lot Floors

• Screed Concrete

Pre-Cast Applications

• Concrete Pipes & Blocks

• Segments

• Retaining Walls

Mining

• Shotcrete

• Passages

Tunnels

• Linings

• Segments

• Slope Stabilization

Packaging Types

• 10 kg packs

• Custom packaging alternatives by application requirements

Mix

Fibers, with a sufficient dosing, can be directly added into mix in the aggregate band. It is also possible to add ENEⓔ Polymacro PM48 to the ready-mix truck ensuring proper distribution within concrete.

For adequate mixing high speed, 5 to 6 minutes revolutions are required after the addition of final dosage.

Storage & Disposal

• It is recommended to store fibers within original packages, between +5°C and 30°C, protected from moisture and direct sunlight.

• Should not be stored near flammable or oxidizing materials.

• Should not be stacked on top of each other unless proper precautions are taken.

Technical data sheet

Please fill the form below to contact our technical team.