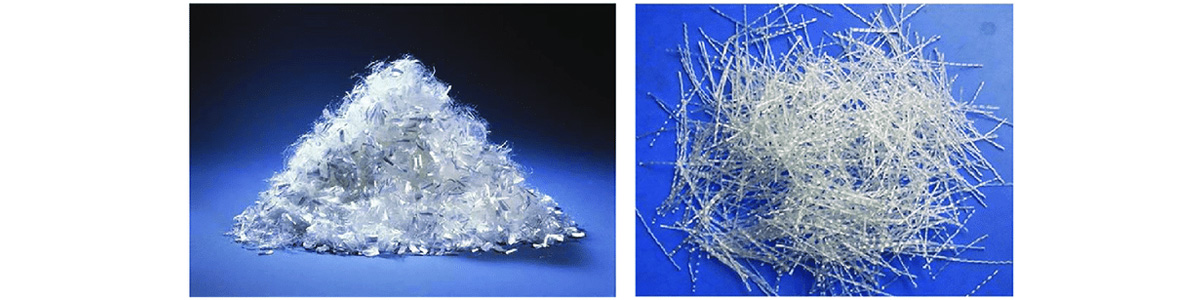

Polyproplene Micro Fiber

Mitigates shrinkage/temperature cracks.

100% alkali resistant. Non-corrosive. No chemical reaction.

Long term resistance to deterioration when in contact with moisture and alkalis present in cement paste or the substances present in air-entraining and chemical admixtures.

Increases durability and service life of concrete.

Reduces freeze/thaw damage and mitigate permeability of water and chemicals into concrete due to three-dimensional effect of the fibers within the concrete mix.

Used in shotcrete applications reducing rebound greatly and save material.

Significantly reduces application times and direct labor expenses.

Reduces slab thickness as concrete cover is not needed anymore thanks to being non-corrosive.

Prevention of corrosion increases service life and reduces maintenance costs.

Does not damage construction equipment as steel fiber.

Reduces costs of storage and can be stored for long-term.

Overall cost is lower than steel mesh and steel fibers.

Usage Instructions

Depending on the project requirements, recommended dosages vary between 0.3 kg/m³ and 2 kg/m³ Homogeneous mixture is obtained by addition of ENEⓔ Polyproplene micro fiber to the aggrege band at the concrete batching plant or by mixing in a high speed concrete mixer for at least 5 minutes in the field.

Applications

Field & Floor Applications

• Industrial Floors

• Underground and Walk Ways

• Concrete Roads

• Logistics Facility Floors

Coastal Structures & Ports

• Ports and Quays

• Shipyard

• Marinas

Water Control Structures

• Hydroelectric Power Plant

• Irrigation Projects

• Channels

• Drinking Water Projects

Residential Applications

• Parking Lot Floors

• Screed Concrete

Pre-Cast Applications

• Concrete Pipes & Blocks

• Segments

• Retaining Walls

Mining

• Shotcrete

• Passages

Tunnels

• Linings

• Segments

• Slope Stabilization

Packaging Types

• 0.9 kg packs

• Custom packaging alternatives by application requirements

Technical data sheet

Please fill the form below to contact our technical team.